What is the easiest machinable aluminum?

Views: 493 Update date: Apr 30,2024

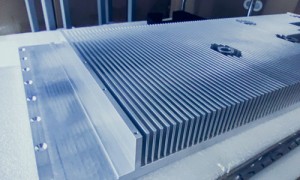

When it comes to aluminum prototype machining, selecting the optimal alloy is paramount to the success of your project. With an array of choices available, identifying the easiest machinable aluminum alloy becomes essential.

After careful consideration, one aluminum alloy emerges as a standout candidate: Aluminum 6061.

Machinability: Aluminum 6061 exhibits outstanding machinability characteristics, facilitating seamless machining processes on lathes and mills. Its low melting point and uniform composition contribute to smooth cutting actions, mitigating tool wear and enhancing operational efficiency.

Strength: Despite its exceptional machinability, Aluminum 6061 does not compromise on strength. Possessing a high strength-to-weight ratio, this alloy ensures structural integrity and longevity, catering to applications demanding robust performance.

Tool Selection: Employ carbide tooling for superior results, as they offer enhanced durability and precision compared to conventional high-speed steel tools.

Speeds and Feeds Optimization: Fine-tune cutting speeds and feeds to suit the unique properties of Aluminum 6061, ensuring optimal performance and surface finish.

Coolant Application: Maintain optimal temperatures and lubrication through consistent coolant application, mitigating heat buildup and prolonging tool life.

Chip Management: Implement effective chip evacuation strategies to prevent chip recutting and surface imperfections, ensuring seamless machining operations.

In Conclusion

In the realm of aluminum prototype machining, the choice of material significantly influences project outcomes. With its unparalleled combination of machinability, strength, and versatility, Aluminum 6061 emerges as the premier selection for machining endeavors. Empower your projects with Aluminum 6061 as the cornerstone of your machining operations, elevating precision and efficiency to new heights.

Prev: Sanwo Metal: Precision Prototyping and Manufacturing Solutions

Next: How to make aluminum parts?

Why Aluminum?

Renowned for its lightweight properties, exceptional durability, and resistance to corrosion, aluminum alloys seamlessly integrate into a multitude of industries, ranging from aerospace to automotive. Furthermore, their superior machinability elevates them to a preferred choice among engineers and manufacturers.The Pursuit of Machinability

In our quest to pinpoint the easiest machinable aluminum alloy, several factors come into play, including machinability, strength, and cost-efficiency. Striking a balance between these attributes ensures optimal performance and reliability in machining operations.After careful consideration, one aluminum alloy emerges as a standout candidate: Aluminum 6061.

Why Aluminum 6061?

Machinability: Aluminum 6061 exhibits outstanding machinability characteristics, facilitating seamless machining processes on lathes and mills. Its low melting point and uniform composition contribute to smooth cutting actions, mitigating tool wear and enhancing operational efficiency.

Strength: Despite its exceptional machinability, Aluminum 6061 does not compromise on strength. Possessing a high strength-to-weight ratio, this alloy ensures structural integrity and longevity, catering to applications demanding robust performance.

Versatility: Whether tasked with intricate component fabrication or structural assemblies, Aluminum 6061 showcases unparalleled versatility. Its adaptability accommodates diverse machining requirements, making it a versatile solution for varied projects.

Tool Selection: Employ carbide tooling for superior results, as they offer enhanced durability and precision compared to conventional high-speed steel tools.

Speeds and Feeds Optimization: Fine-tune cutting speeds and feeds to suit the unique properties of Aluminum 6061, ensuring optimal performance and surface finish.

Coolant Application: Maintain optimal temperatures and lubrication through consistent coolant application, mitigating heat buildup and prolonging tool life.

Chip Management: Implement effective chip evacuation strategies to prevent chip recutting and surface imperfections, ensuring seamless machining operations.

In Conclusion

In the realm of aluminum prototype machining, the choice of material significantly influences project outcomes. With its unparalleled combination of machinability, strength, and versatility, Aluminum 6061 emerges as the premier selection for machining endeavors. Empower your projects with Aluminum 6061 as the cornerstone of your machining operations, elevating precision and efficiency to new heights.