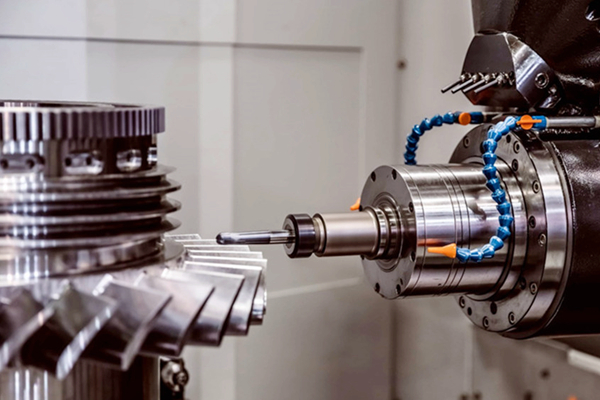

Sanwo precision 5-Axis CNC Machining

At Sanwo, we have multi-Axis CNC machines including the 5-Axis CNC machines, 5-Axis CNC machining is a very important additional process to CNC machining, it is the latest technologies and modern manufacturing methods able to move the tool or work Parts on five axes at once to get a precision and smooth surface product. For 5-Axis CNC machining, the cutting tool moves across the X, Y, and Z linear axes just like the 3-axis CNC machining, beyond that, it also rotates on the A and B axes to get approach the work parts from all directions. As a result, 5-Axis CNC can machine from five sides with one setup.

Contact us for a 5-Axis CNC Machining inquiry.

What is the advantages of Precision 5-Axis CNC Machining

As 5-axis technology develops, the process is becoming easier to programming and navigate . it is safe and easy to operate because all of the complexities have been built into the machine.By adding an axis of rotation around the X and Y linear axes, 3+2-Axis CNC Machining is the most time consuming and tight tolerance precision machining process for CNC machining. It is advantages on producing complex parts and strict manufacture requirements,

Time consuming

The 5-Axis machining equipment were developed to allow the milling, cutting, turning, boring, threading and tapping processes to be automated in one machine at once and taking the advantages of rotating two more axes upon X,Y and Z planes. These two more axes approach the workpiece from any direction enabling the undercutting or complex geometries and surfaces to be make without any re-positioned, in which parts can be produce quickly and efficiently in high precision.

Tight tolerance

Unlike 3-Axis machining for complex parts which needs to be re-positioned and remove workpiece from machine, 5-Axis machining completes the parts in a single set up, and reduce the tolerance missing during part re-positioned. With the best technological program and high precision tools, 5 Axis CNC machining is an ideal process for high precision parts in tight tolerance.

APPLICATIONS OF 5-AXIS CNC MACHINING

5-axis CNC machining is a cutting-edge manufacturing process that enhances precision, efficiency, and complexity in machining operations. Here are some key applications:

5-axis CNC machining is a cutting-edge manufacturing process that enhances precision, efficiency, and complexity in machining operations. Here are some key applications:

Aerospace Components

5-axis machines are essential for producing intricate parts such as turbine blades, airframes, and engine components. The ability to machine complex geometries and tight tolerances is crucial in this industry.

Automotive Industry

These machines are used for manufacturing components like engine blocks, transmission cases, and custom parts, allowing for efficient production and reduction of setup times.

Medical Devices

Precision is vital in the medical field. 5-axis CNC machining is used to create complex implants, surgical tools, and prosthetics, ensuring high levels of accuracy and surface finish.

Mold and Die Making

This technology is ideal for creating molds and dies with intricate designs. The ability to access various angles without repositioning the workpiece reduces cycle times and increases efficiency.

Tool and Fixture Production

5-axis machining allows for the rapid production of custom tools and fixtures, essential for maintaining precision in manufacturing processes.

Aesthetic and Artistic Applications

Artists and designers use 5-axis CNC machines to create intricate sculptures, furniture, and decorative items, enabling the realization of complex shapes and patterns.

Research and Development

In R&D, 5-axis machining facilitates the rapid prototyping of components, allowing engineers to iterate designs quickly and test functionality.

Oil and Gas Industry

Components for drilling equipment, valves, and fittings often require the precision that 5-axis machining provides, enabling the manufacture of complex geometries needed for efficient operation.

Defense Applications

The manufacturing of precision components for weapons systems and military vehicles relies on the advanced capabilities of 5-axis CNC machines.

Consumer Electronics

These machines can produce intricate casings and components for electronic devices, ensuring both functionality and aesthetic appeal.

Overall, 5-axis CNC machining is a versatile and powerful tool in modern manufacturing, enabling the production of complex and high-quality parts across various industries.

SAMPLE PRODUCTS

FAQ

5-Axis machining FAQ

How do I know my design will be kept confidential?

We of course will sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever allowed of a customer’s product without express permission. Ultimately we rely on our reputation of working with hundreds of thousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

When do I need a 5-Axies CNC process?

5-Axis CNC machining has the freedom of motion to produce some very complex geometries, when the Standard 3-axis CNC machines can't move the cutting tool in a manner that a 5-Axies CNC process is needed, send us an CNC inquiry, we will reply you back on the suggestions.

How Long can I get a 5-Axies CNC machining quote?

5-Axies CNC machining just like the normal quoting, depend on the volume of part needs 24-72hours, for prototype quotes provide within 24 hours.

What is the most popular application in Sanwo precision5-Axies CNC machining ?

Most of the time, the complicate and high tolerance parts will choose 5-Axies CNC machining, Auto Industrial like the Aluminum lamp reflector, lens holding and concept cars, Consumer Electronic industrial like the moto Blades and windmill blades, Medical industrial like medical impellers and CT Scanner components. Aerospace Industrial like Turbine blades.